CONVAL TOOLBOX

Exploring CONVAL: Essential Tools for Engineering from F.I.R.S.T. GmbH

Available from DP-Flow Ltd

CONVAL by F.I.R.S.T. GmbH is a specialized software platform designed for process engineering tasks, known for its comprehensive toolset that streamlines technical calculations in industrial applications. From sizing control valves to analyzing thermodynamic properties, CONVAL integrates various modules and features that enhance accuracy, productivity, and ease of use. Here’s a look at the key tools within CONVAL:

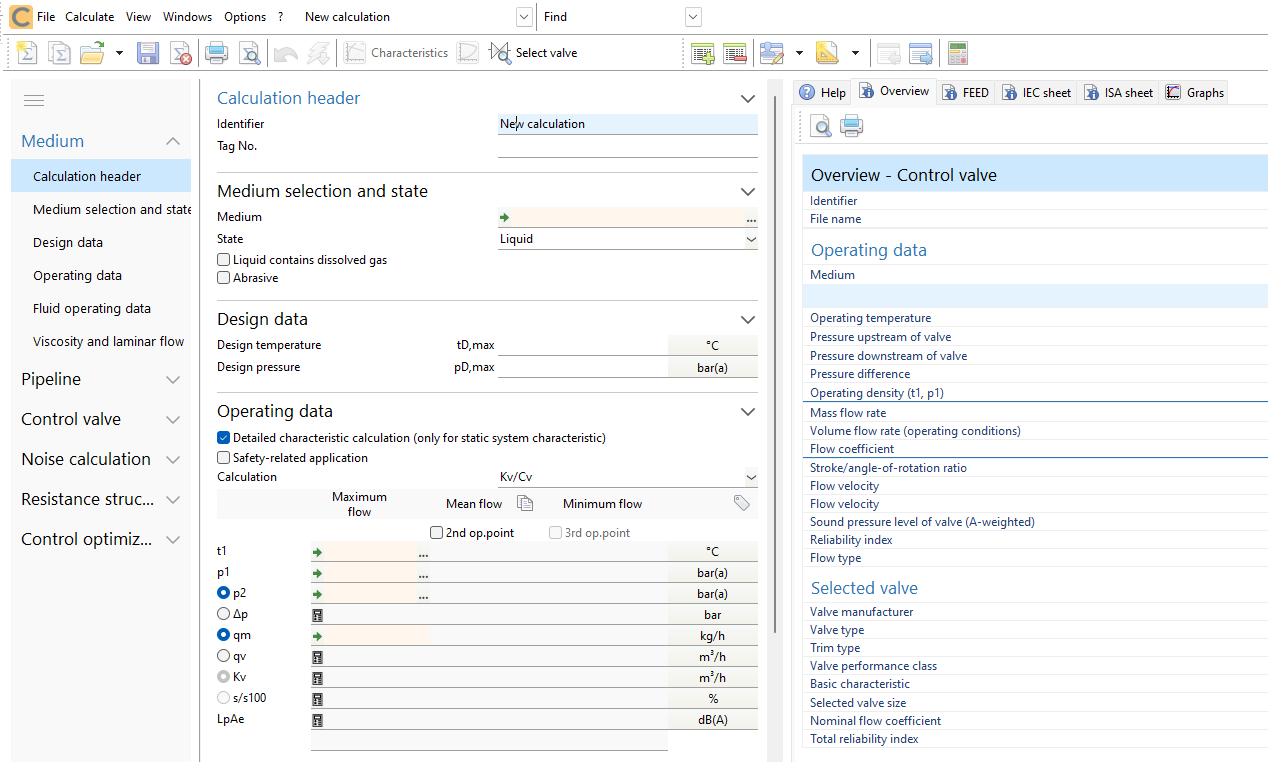

1. Valve Sizing and Selection

CONVAL’s core strength lies in its ability to accurately size and select valves. With compliance to global standards like IEC, ISA, and VDI, the tool helps engineers find the right control valves for specific applications. The module enables quick assessments of different valve types and materials to ensure optimal flow control, supporting both incompressible and compressible fluids with real-time performance simulation.

2. Thermodynamic and Fluid Property Calculations

Engineers often require precise data on fluid properties such as density, viscosity, and enthalpy, particularly when dealing with complex fluids. CONVAL integrates advanced thermodynamic models to simulate these properties based on temperature and pressure. With its extensive database, it can handle a wide range of fluids and gases, making it a vital tool for applications in chemical and process engineering.

3. Pipeline and Pressure Drop Calculations

For pipeline systems, CONVAL provides accurate pressure drop calculations by accounting for the flow regime, pipe roughness, and other influencing factors. This tool allows engineers to analyze and optimize pipeline designs, ensuring sufficient flow rates while minimizing energy loss. It also includes tools for two-phase flow calculations, which are crucial in industries like oil & gas where mixed-phase fluids are common.

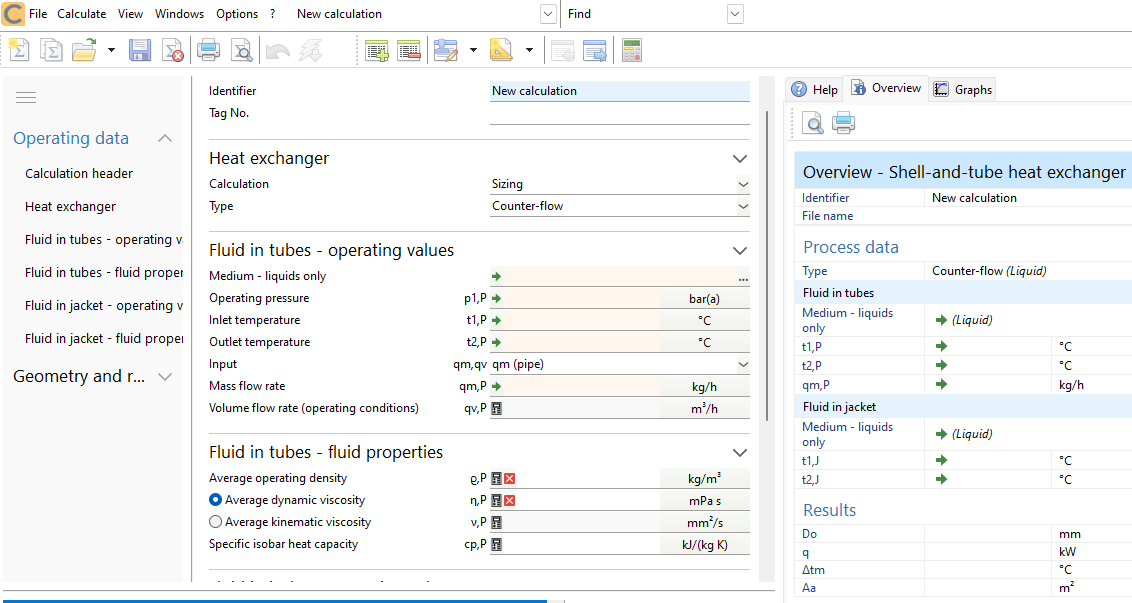

4. Heat Exchanger Calculations

Efficient heat exchanger operation is critical in many industries, and CONVAL offers tools to design, size, and analyze both shell-and-tube and plate heat exchangers. The software enables users to estimate thermal performance and evaluate heat transfer efficiency, allowing for proper sizing and optimization of these devices to ensure maximum operational efficiency.

5. Noise Prediction in Valves and Pipelines

Noise can be a significant issue in process facilities, affecting worker safety and regulatory compliance. CONVAL’s noise prediction tool helps engineers assess and mitigate noise levels in control valves and piping systems, ensuring adherence to ISO and IEC standards. This module provides noise calculations for different valve types and conditions, helping engineers design quieter, safer systems.

6. Safety Valve Sizing

For systems that require pressure relief, CONVAL includes tools for sizing safety valves according to various standards (such as API and ASME). The software supports engineers in selecting the appropriate relief valves to safeguard systems against overpressure, factoring in different scenarios and fluids to ensure reliable protection under abnormal operating conditions.

Why Choose CONVAL?

The seamless integration of these tools within CONVAL makes it a powerful asset for process engineers, offering precision, compliance with international standards, and a user-friendly interface. By consolidating multiple technical calculations into one platform, CONVAL reduces the need for additional software and manual cross-checking, making engineering workflows more efficient and accurate.

With these tools, F.I.R.S.T. GmbH continues to support engineers in creating robust, efficient, and safe process systems across industries like energy, chemical, pharmaceutical, and oil & gas. Whether you’re designing a new system or optimizing an existing one, CONVAL provides the tools you need for confident, data-driven engineering decisions.