CFS400A Coriolis Flow Sensor

Unmatched Precision for Bulk Flow Measurement and Custody Transfer

Product Overview:

CFS400A Coriolis Flow Sensor

The CFS400A Coriolis Flow Sensor by Schneider Electric is designed for high-precision bulk measurement and custody transfer of liquids and gases. With robust stainless steel measuring tubes and an optional Super Duplex variant, this flow sensor meets the stringent demands of the oil and gas industry while also being versatile enough for other industrial applications. The CFS400A leverages advanced Coriolis technology, ensuring accurate measurement of mass, density, and volume without the need for external calibration devices. Its comprehensive diagnostic capabilities and modular electronics make it a reliable choice for high-stakes operations.

Key Facts and Features

-

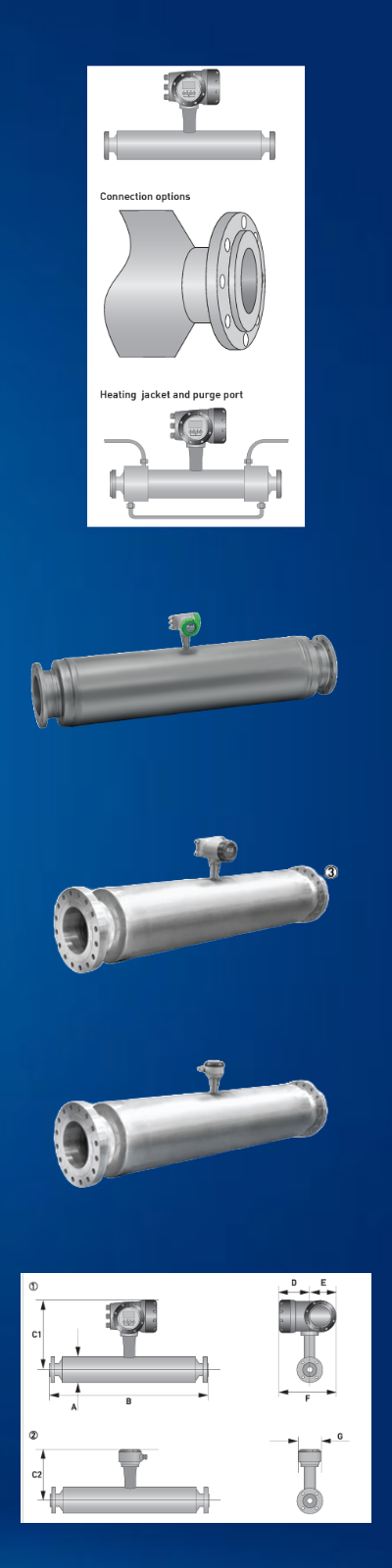

Design: Multiple large measuring tubes for high flow rate capacity

- Materials: Stainless Steel measuring tubes (NACE compliant) and Super Duplex option (up to 180 barg)

- Accuracy:

- Liquid: ±0.1% (standard), ±0.05% (optional)

- Gas: ±0.35%

- Density: ±1.0 kg/m³ (standard), ±0.2 kg/m³ (on-site calibration)

- Construction: Fully welded, maintenance-free sensor with multiple straight measuring tubes

- Temperature: Optional heating jacket to prevent solidification of products

- Safety: Secondary containment up to 150 barg and optional purge port for hazardous chemicals

- Connectivity: Standard flange process connections available

Industries and Applications

Industries:

- Marine

- Oil and gas

- Wastewater

- Chemical

- Paper and pulp

- Pharmaceutical

- Fresh water

Applications:

- Bulk loading/unloading

- Custody transfer for volume and mass

- High volume pipeline measurement

- Allocation metering

Benefits

- High Accuracy: Ensures precise custody transfer and bulk measurement

- Robust Construction: Long-lasting performance with minimal maintenance

- Versatile Connectivity: Compatible with various flange sizes and standards

- Advanced Diagnostics: Comprehensive monitoring capabilities for enhanced reliability

- Temperature Management: Optional heating jacket for handling temperature-dependent products

- Enhanced Safety: Secondary containment and purge port options for safe handling of hazardous chemicals

Technical Data

- Measuring Principle: Coriolis mass flow using multiple tubes

- Measured Values: Mass, density, temperature

- Calculated Values: Volume, referred density, concentration, velocity

- Repeatability: Better than ±0.05% for liquids and ±0.2% for gases

- Flow Rates:

- Nominal: Up to 2,400,000 kg/h (S400 model)

- Maximum: Up to 4,600,000 kg/h (S400 model)

- Operating Conditions:

- Ambient Temperature: -40°C to +65°C depending on the model and configuration

- Process Temperature: -45°C to +130°C

- Pressure Ratings:

- Stainless Steel: Up to 150 barg

- Super Duplex: Up to 180 barg

- Protection: IP66/67, NEMA 4X

- Approvals: CE, ATEX, cFMus, ANSI/CSA, Custody Transfer, MID MI 002 and MI 005, OIML R117-1

Download PDF: Foxboro CFS300 Coriolis Flowtube Datasheet.pdf

Supplied by DP-Flow

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222