EPI Insertion Products

EPI AirLine™ AL41 Insertion Thermal Mass Flow Meter

Description

The Eldridge Product, Inc. (EPI) Series AirLine AL41 Insertion Mass Flow Meter is the all new series of thermal mass flow meters designed to aid in the measurement and management of compressed air systems’ consumption and usage. Low cost and offered in a 316 Stainless Steel 6” probe length with extremely fast response time. Get yours today and rest assured with the accurate and reliable capability of the AirLine Series thermal mass flow meter from Eldridge Products, the AirLine Series AL41 Flow Meters are compact Insertion style instruments. The CNC machined 316 Stainless Steel Probe is specified to be inserted directly into the user’s process line; with the ability to be inserted into a compressed air process line of up to 4″. The Series AL41 features a thermal glass coated ceramic sensor for the ultimate in fast response time. The sensing elements are mounted directly in the end of the probe for exposure to the process gas. All electronics are mounted integrally on the flow section in an aluminum NEMA 4X (IP66) enclosure.

EPI BlueMax™ BM41 Insertion Thermal Mass Flow Meter

Description

The Eldridge Product, Inc. (EPI) Series BlueMax™ BM41 offers another lower cost option for “boiler” flow applications with the high value associated with all of EPI's flow measurement instrumentation.

BlueMax™ flow meters include a robust feature set: 0 – 5, 10 VDC, 4 – 20mA, RS485 Modbus RTU and optional 0 – 1 kHz outputs (proportional to the gas mass flow rate); an RS232C port; 16-bit linearization technology for flow rate accuracy; a fully programmable relay; and rugged construction of 316/316L stainless steel wetted parts. An optional 2-line, 16-character backlit LCD displays the flow rate and the elapsed total readouts.

BlueMax™ inline and insertion flow meters accommodate virtually all installation requirements. The Series BM-41 insertion style flow meters are available with 6”, 12” or 18” long probes (Optional compression fitting for mounting). Other mounting options are available. BlueMax™ flow meters accept 24VDC, 115VAC or 230VAC input power as specified at the time of purchase.

EPI Series 7000 Insertion Thermal Mass Flow Switch

Model

7240 – 1/2″ diameter probe, max length 36″

7260 – 3/4″ diameter probe, max length 60″

7280 – 1″ diameter probe, max length 84″

Description

The Eldridge Product, Inc. (EPI) Insertion style flow switch series 7000 includes a sensor probe assembly which is inserted into the process conduit to allow the gas to flow across the sensors. The insertion style thermal mass flow switch probe assemblies may be inserted into any suitable flow section, pipe, duct, etc.

Insertion flow switches are available with 1/2″, 3/4″, or 1″ OD probes and may be installed with pipe fitting connections or user-supplied bored through tube fittings. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length must be specified upon ordering. For other probe diameters and lengths, please consult the factory.

All of EPI’s flow switches have two single-pole, double-throw relays for Hi/Hi, Lo/Lo and Hi/Lo capability. The contact closure is 5 amps @ 24 VDC and 115 VAC. Two LEDs are provided for verification that the Hi or Lo alarm has been triggered. The standard configuration has 316 Stainless Steel wetted parts (Hastelloy & Monel are also available) for a rugged, cleanable instrument designed for use in applications where corrosion, abrasion, high pressure or rough handling may be expected

EPI Series 8200 MPNH Insertion Remote Thermal Mass Flow Meter

Description

The EIdridge Product, Inc. (EPI) insertion style thermal mass flow meter series 8200 MPNH includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow sensing elements. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length must be specified upon ordering. For other probe diameters and lengths, please consult the factory.

Remote style thermal mass flow meters utilize two enclosures. One enclosure is mounted at the point of measurement on the flow section or on the probe assembly. This enclosure may be rated for either hazardous environments or for ordinary, non-hazardous environments, as necessary. The second (remote) enclosure is usually placed in a readily accessible location rated for non-hazardous conditions. (Contact the factory for information concerning remote explosion-proof enclosure). The remote enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly. Only a four-wire, twisted-pair cable is required to carry the input power and flow signal between the two enclosures.

Thermal mass flow meters use the principle of convective heat transfer to directly measure mass flow. EPI’s proprietary thermal mass flow sensors use two ratiometrically-matched, reference-grade platinum Resistance Temperature Detectors (RTDs). The platinum sensing element wire is encapsulated in a 316 Stainless Steel sheath or, if specified, a Hastelloy C sheath. Our microcontroller operated smart sensor technology preferentially heats one RTD; the other RTD acts as the temperature reference. The process gas flow dissipates heat from the first RTD, causing an increase in the power required to maintain a balance between the RTDs. This increase is directly related to the gas molecular rate of flow. Our sensors are temperature compensated for a wide process gas temperature range and insensitive to pressure changes, so the output signal is a true mass flow rate signal.

EPI Series 8200MP Insertion Remote Thermal Mass Flow Meter

Description

The Eldridge Product, Inc. (EPI) Insertion style thermal mass flow meter series 8200MP includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow sensing elements. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length must be specified upon ordering. For other probe diameters and lengths, please consult the factory.

Remote style thermal mass flow meters utilize two enclosures. One enclosure is mounted at the point of measurement on the flow section or on the probe assembly. This enclosure may be rated for either hazardous environments or for ordinary, non-hazardous environments, as necessary. The second (remote) enclosure is usually placed in a readily accessible location rated for non-hazardous conditions. (Contact the factory for information concerning remote explosion-proof enclosure). The remote enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly. Only a four-wire, twisted-pair cable is required to carry the input power and flow signal between the two enclosures.

Thermal mass flow meters use the principle of convective heat transfer to directly measure mass flow. EPI’s proprietary thermal mass flow sensors use two ratiometrically-matched, reference-grade platinum Resistance Temperature Detectors (RTDs). The platinum sensing element wire is encapsulated in a 316 Stainless Steel sheath or, if specified, a Hastelloy C sheath. Our microcontroller operated smart sensor technology preferentially heats one RTD; the other RTD acts as the temperature reference. The process gas flow dissipates heat from the first RTD, causing an increase in the power required to maintain a balance between the RTDs. This increase is directly related to the gas molecular rate of flow. Our sensors are temperature compensated for a wide process gas temperature range and insensitive to pressure changes, so the output signal is a true mass flow rate signal.

EPI Series 8200MPHT Insertion Remote Thermal Mass Flow Meter High Temperature

Description

The Eldridge Product,Inc. (EPI) Insertion style thermal mass flow meter series 8200MPHT includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow sensing elements. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length must be specified upon ordering. For other probe diameters and lengths, please consult the factory.

Remote style thermal mass flow meters utilize two enclosures. One enclosure is mounted at the point of measurement on the flow section or on the probe assembly. This enclosure may be rated for either hazardous environments or for ordinary, non-hazardous environments, as necessary. The second (remote) enclosure is usually placed in a readily accessible location rated for non-hazardous conditions. (Contact the factory for information concerning remote explosion-proof enclosure). The remote enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly. Only a four-wire, twisted-pair cable is required to carry the input power and flow signal between the two enclosures.

Thermal mass flow meters use the principle of convective heat transfer to directly measure mass flow. EPI’s proprietary thermal mass flow sensors use two ratiometrically-matched, reference-grade platinum Resistance Temperature Detectors (RTDs). The platinum sensing element wire is encapsulated in a 316 Stainless Steel sheath or, if specified, a Hastelloy C sheath. Our microcontroller operated smart sensor technology preferentially heats one RTD; the other RTD acts as the temperature reference. The process gas flow dissipates heat from the first RTD, causing an increase in the power required to maintain a balance between the RTDs. This increase is directly related to the gas molecular rate of flow. Our sensors are temperature compensated for a wide process gas temperature range and insensitive to pressure changes, so the output signal is a true mass flow rate signal.

EPI Series 8800MP Insertion Thermal Mass Flow Meter

Description

The Eldridge Product, inc. (EPI) Insertion style thermal mass flow meter series 8800MP includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow sensing elements. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length must be specified upon ordering. For other probe diameters and lengths, please consult the factory.

Integral style thermal mass flow meters have all of the electrical components and connections located within one enclosure. This enclosure may be rated for either hazardous environments (MP Series) or for ordinary, non-hazardous environments (MPNH Series), as necessary. The enclosure is mounted directly to the inline flow section or to the insertion probe assembly at the point of measurement. The enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly.

Thermal mass flow meters use the principle of convective heat transfer to directly measure mass flow. EPI’s proprietary thermal mass flow sensors use two ratiometrically-matched, reference-grade platinum Resistance Temperature Detectors (RTDs). The platinum sensing element wire is encapsulated in a 316 Stainless Steel sheath or, if specified, a Hastelloy C sheath. Our microcontroller operated smart sensor technology preferentially heats one RTD; the other RTD acts as the temperature reference. The process gas flow dissipates heat from the first RTD, causing an increase in the power required to maintain a balance between the RTDs. This increase is directly related to the gas molecular rate of flow. Our sensors are temperature compensated for a wide process gas temperature range and insensitive to pressure changes, so the output signal is a true mass flow rate signal.

EPI Series 8800MPHT Insertion Thermal Mass Flow Meter High Temperature

Description

The Eldridge Product, inc. (EPI) Insertion style thermal mass flow meter series 8800 MPHT includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow sensing elements. Our insertion style flow meters are available with 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length must be specified upon ordering. For other probe diameters and lengths, please consult the factory.

Integral style thermal mass flow meters have all of the electrical components and connections located within one enclosure. The enclosure is mounted directly to the insertion probe assembly at the point of measurement. The enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly.

Thermal mass flow meters use the principle of convective heat transfer to directly measure mass flow. EPI’s proprietary thermal mass flow sensors use two ratiometrically-matched, reference-grade platinum Resistance Temperature Detectors (RTDs). The platinum sensing element wire is encapsulated in a 316 Stainless Steel sheath or, if specified, a Hastelloy C sheath. Our microcontroller operated smart sensor technology preferentially heats one RTD; the other RTD acts as the temperature reference. The process gas flow dissipates heat from the first RTD, causing an increase in the power required to maintain a balance between the RTDs. This increase is directly related to the gas molecular rate of flow. Our sensors are temperature compensated for a wide process gas temperature range and insensitive to pressure changes, so the output signal is a true mass flow rate signal.

EPI Series 8800MPNH Insertion Thermal Mass Flow Meter

Description

The Eldridge Product, Inc. (EPI) Insertion style thermal mass flow meter series 8800MPNH includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow sensing elements. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length must be specified upon ordering. For other probe diameters and lengths, please consult the factory.

Integral style thermal mass flow meters have all of the electrical components and connections located within one enclosure. This enclosure may be rated for either hazardous environments (MP Series) or for ordinary, non-hazardous environments (MPNH Series), as necessary. The enclosure is mounted directly to the inline flow section or to the insertion probe assembly at the point of measurement. The enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly.

Thermal mass flow meters use the principle of convective heat transfer to directly measure mass flow. EPI’s proprietary thermal mass flow sensors use two ratiometrically-matched, reference-grade platinum Resistance Temperature Detectors (RTDs). The platinum sensing element wire is encapsulated in a 316 Stainless Steel sheath or, if specified, a Hastelloy C sheath. Our microcontroller operated smart sensor technology preferentially heats one RTD; the other RTD acts as the temperature reference. The process gas flow dissipates heat from the first RTD, causing an increase in the power required to maintain a balance between the RTDs. This increase is directly related to the gas molecular rate of flow. Our sensors are temperature compensated for a wide process gas temperature range and insensitive to pressure changes, so the output signal is a true mass flow rate signal.

EPI Series 9200MP Insertion Remote Flow Averaging Tube (FAT) Thermal Mass Flow Meter

Description

The Eldridge Product,Inc. (EPI) Insertion style thermal mass flow meter series 9200MP includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow inlet tube. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length is determined by the size of the process pipe. Large ducts or stacks may require multiple averaging tubes to achieve the very best accuracy. For problematic or unique installations, please consult the factory.

Remote style thermal mass flow meters utilize two enclosures. One enclosure is mounted at the point of measurement on the flow section or on the probe assembly. This enclosure may be rated for either hazardous environments or for ordinary, non-hazardous environments, as necessary. The second (remote) enclosure is usually placed in a readily accessible location rated for non-hazardous conditions. (Contact the factory for information concerning remote explosion-proof enclosure). The remote enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly.

Our patented Flow Averaging Tubes™ (FAT™) use the principle of convective heat transfer to directly measure mass flow, and are well suited to most applications with limited available straight run. In many installations, the up-stream straight run can be reduced to three diameters. The probe has a number of large diameter inlet ports along the length of the upstream impact surface. The pressure at each inlet port is averaged inside the tube to create the axial flow through the tube and across our flow sensor. The gas returns to the main flow stream through the ports located near the sensing elements. Anomalies in the actual flow profile or installations in non-circular ducts may still some require minor adjustment to achieve the best accuracy.

EPI Series 9200MPNH Insertion Remote Flow Averaging Tube (FAT) Thermal Mass Flow Meter

Description

The Eldridge Product,Inc. (EPI) Insertion style thermal mass flow meter series 9200MPNH includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow inlet tube. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length is determined by the size of the process pipe. Large ducts or stacks may require multiple averaging tubes to achieve the very best accuracy. For problematic or unique installations, please consult the factory.

Remote style thermal mass flow meters utilize two enclosures. One enclosure is mounted at the point of measurement on the flow section or on the probe assembly. This enclosure may be rated for either hazardous environments or for ordinary, non-hazardous environments, as necessary. The second (remote) enclosure is usually placed in a readily accessible location rated for non-hazardous conditions. (Contact the factory for information concerning remote explosion-proof enclosure). The remote enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly.

Our patented Flow Averaging Tubes™ (FAT™) use the principle of convective heat transfer to directly measure mass flow, and are well suited to most applications with limited available straight run. In many installations, the up-stream straight run can be reduced to three diameters. The probe has a number of large diameter inlet ports along the length of the upstream impact surface. The pressure at each inlet port is averaged inside the tube to create the axial flow through the tube and across our flow sensor. The gas returns to the main flow stream through the ports located near the sensing elements. Anomalies in the actual flow profile or installations in non-circular ducts may still some require minor adjustment to achieve the best accuracy.

EPI Series 9800MP Insertion Flow Averaging Tube (FAT) Thermal Mass Flow Meter

Description

The Eldridge Product, Inc. (EPI) Insertion style thermal mass flow meter series 9800MP includes a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow inlet tube. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length is determined by the size of the process pipe. Large ducts or stacks may require multiple averaging tubes to achieve the very best accuracy. For problematic or unique installations, please consult the factory.

Integral style thermal mass flow meters have all of the electrical components and connections located within one enclosure. This enclosure may be rated for either hazardous environments (MP Series) or for ordinary, non-hazardous environments (MPNH Series), as necessary. The enclosure is mounted directly to the inline flow section or to the insertion probe assembly at the point of measurement. The enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly.

Our patented Flow Averaging Tubes™ (FAT™) use the principle of convective heat transfer to directly measure mass flow, and are well suited to most applications with limited available straight run. In many installations, the up-stream straight run can be reduced to three diameters. The probe has a number of large diameter inlet ports along the length of the upstream impact surface. The pressure at each inlet port is averaged inside the tube to create the axial flow through the tube and across our flow sensor. The gas returns to the main flow stream through the ports located near the sensing elements. Anomalies in the actual flow profile or installations in non-circular ducts may still some require minor adjustment to achieve the best accuracy.

EPI Series 9800MPNH Insertion Flow Averaging Tube (FAT) Thermal Mass Flow Meter

Description

The Eldridge Product, Inc. (EPI) Insertion style thermal mass flow meter series 9800MPNH include a sensor & probe assembly that is inserted into the process gas flow conduit to allow the process gas to flow across the flow inlet tube. Our insertion style flow meters are available with 1/2″, 3/4″, or 1″ OD probes. Tube fittings and ball valve retractor assemblies, with or without a mounting flange, are also available from the factory as options. The tube length is determined by the size of the process pipe. Large ducts or stacks may require multiple averaging tubes to achieve the very best accuracy. For problematic or unique installations, please consult the factory.

Integral style thermal mass flow meters have all of the electrical components and connections located within one enclosure. This enclosure may be rated for either hazardous environments (MP Series) or for ordinary, non-hazardous environments (MPNH Series), as necessary. The enclosure is mounted directly to the inline flow section or to the insertion probe assembly at the point of measurement. The enclosure includes the all of the electrical connections as well as the linearizing electronics and the display/keypad assembly.

Our patented Flow Averaging Tubes™ (FAT™) use the principle of convective heat transfer to directly measure mass flow, and are well suited to most applications with limited available straight run. In many installations, the up-stream straight run can be reduced to three diameters. The probe has a number of large diameter inlet ports along the length of the upstream impact surface. The pressure at each inlet port is averaged inside the tube to create the axial flow through the tube and across our flow sensor. The gas returns to the main flow stream through the ports located near the sensing elements. Anomalies in the actual flow profile or installations in non-circular ducts may still some require minor adjustment to achieve the best accuracy.

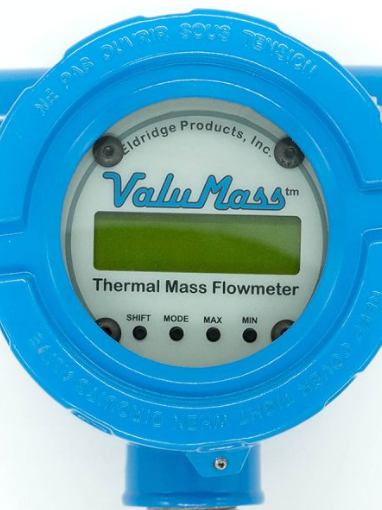

EPI ValuMass™ 440 Insertion Thermal Mass Flow Meter

Description

The Eldridge Product, Inc. (EPI) ValuMass™ Series 440 offers another lower cost option for many flow applications with the high value associated with all of EPI’s flow measurement instrumentation.

ValuMass™ flow meters include a robust feature set: 0 – 5, 10 VDC, 4 – 20mA, RS485 Modbus RTU and optional 0 – 1 kHz outputs (proportional to the gas mass flow rate); an RS232C port; 16-bit linearization technology for flow rate accuracy; a fully programmable relay; and rugged construction of 316/316L stainless steel wetted parts. An optional 2-line, 16-character backlit LCD displays the flow rate and the elapsed total readouts.

ValuMass™ inline and insertion flow meters accommodate virtually all installation requirements. The Series 440 insertion style flow meters are available with 6”, 12” or 18” long probes (Optional compression fitting for mounting). Other mounting options are available. ValuMass™ flow meters accept 24VDC, 115VAC or 230VAC input power as specified at the time of purchase.

EPI ValuMass™ 540 Insertion Thermal Mass Flow Meter

Description

The Eldridge Product,Inc. (EPI) Master-Touch™ series 540 thermal dispersion gas mass flow meter and patented Flow Averaging Tubes set the standard for innovation, performance and reliability. Now our Series 500 ValuMass™ flow meters offer a lower cost option for many flow applications with the high value associated with all of EPI’s flow measurement instrumentation.

The Series 500 ValuMass™ flow meters include 16-bit linearization technology for excellent flow rate accuracy and rugged construction of 316L stainless steel wetted parts.

EPI Series 9000MP Multipoint Thermal Mass Flow Meter

Description

The Eldridge Product,Inc. (EPI) Multipoint System series 9000MP are designed to measure gas flows where two or more sensing points are required due to large cross-sectional areas, such as large air intake ducts or air exhaust and flue stacks. Our Series 9000MP Multipoint Systems are installed throughout the world, providing our customers with years of steady, reliable service. Coupled with our new Air Purge System, the Series 9000MP Multipoint Systems are now well-suited to an even greater variety of industrial applications. The probe design supports applications as diverse as ambient air flows in HVAC ducts, exhaust gas in large diameter stacks, boiler NOx efficiency systems and municipal waste incinerators. Our customers include environmental/HVAC system integrators, pulp & paper mills, power & energy companies, etc. across the US, Europe and Asia. The configuration and installation options support facility retrofits as well as the most modern new construction requirements.

Configuration

The Series 9000MP Multipoint System includes one or more Series 9000MP Probes and a Series 9600MP System Control Panel. The 9000MP flow transmitter probe assembly is the heart of the system. The probe assembly typically has two or more flow sensors mounted in a 1½” OD probe shaft. The 9000MP probe’s sensors are removable for field replacement if one is damaged. Each sensor is matched to its own bridge board and microprocessor to function, in effect, as a complete flow meter. The linearized output signals from the multiple sensor assemblies in each probe are averaged to create one overall probe output signal.

The probe’s averaged output signal is transmitted to a Series 9600MP System Control Panel (SCP). If more than one probe is installed, the output signals from all of the probes are transmitted to the SCP for averaging to create one system output. The System Control Panel (SCP) is housed in a 12″ x 10″ NEMA 4X fiberglass enclosure. The SCP provides the power for the probe assemblies and receives the averaged outputs over a four-wire cable to each probe. It also includes its own microprocessor assembly for system-level control and flow display. The SCP provides two analog output signals (0–5 VDC and 4–20 mA), as well as RS232 & RS485 Modbus RTU communications. The 4–20 mA grand average output can drive up to 1200 ohms.

Optional Air Purge System

The optional Air Purge System (APS) provides a means of cleaning the sensors in applications where particulates cause problems. The frequency and duration of the purge cycle can be controlled externally or by using the Master-Touch™ software. The system can also be set to maintain the flow rate at its level when the purge was activated. This important option preserves the integrity of the flow rate and elapsed total data which might otherwise be compromised by the flow of the purge gas.

EPI Series 9600MP System Control Panel (SCP)

Description

The Eldridge Product,Inc. (EPI) System Control Panel (SCP) series 9600MP provides the ability to average multiple sensors for one output flowrate. It can be used with all of our single point or multipoint meters. This allows for a variety of system configurations to address flow profiles that require sensors in various cross sectional positions. You can use our low cost meters on up to our more elaborate multipoint system.

The multiple probes’ output signals are transmitted to a Series 9600MP System Control Panel (SCP) via Modbus RTU communications. At its most basic, this system provides an analog “grand average” output. However, the system’s local Modbus network design also supports communications with each Series MP flow meter, as well as the overall system, for an unparalleled level of command and control when accessed by the user though the Modbus interface.

The System Control Panel (SCP) is housed in a 12″ x 10″ NEMA 4X fiberglass enclosure. The SCP provides the power for the probe assemblies and receives the averaged outputs over a four-wire cable to each probe. It also includes its own microprocessor assembly for system-level control and flow display. The SCP provides two analog output signals (0–5 VDC and 4–20 mA), as well as RS232 & RS485 Modbus RTU communications. The 4–20 mA grand average output can drive up to 1200 ohms. 2-line, 16 character LCD with 4 button keypad for system level control.

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222