Knick SensoGate

SensoGate: The SenSation

SensoGate: The SenSation

Overview

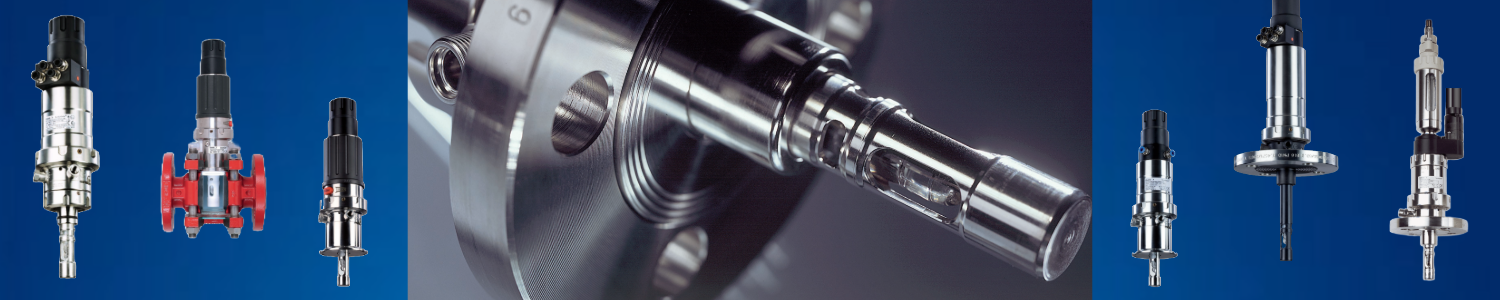

The renowned SensoGate retractable fittings are now available in hygienic versions, making them perfect for manual, semi-automatic, or fully automatic measurement, cleaning, and calibration processes. Featuring a unique modular design, SensoGate fittings accommodate all common process connections and allow for easy replacement of process-wetted parts. This flexibility enables seamless switching between solid-electrolyte and pressurizable liquid-electrolyte sensors. SensoGate fittings come in various process-resistant materials, including PVDF, PEEK, 1.4435, 1.4571, and Hastelloy, ensuring durability and adaptability for a wide range of applications.

Key Features |

|||

|

Unique Safety:

Versatile Materials:

Hygienic Applications:

ATEX Approval:

|

|

||

|

|

|||

Download PDF: Knick SensoGate Sensor Lock-Gates PDF

SensoGate Product Range

WA 130 - SensoGate Retractable Fitting

The SensoGate WA 130 is a universal, pneumatically operated retractable fitting designed for fully automatic operation. Its modular design ensures minimal maintenance, maximum flexibility, and ease of use. With a central multiplug connecting all media and control mechanisms, it offers a safe, convenient, and efficient setup.

Facts and Features

Compact and Smooth Design: Dirt-resistant with interior media routing and an integrated limit-position mechanism.

Compact and Smooth Design: Dirt-resistant with interior media routing and an integrated limit-position mechanism.- Modular Design: Facilitates low maintenance costs and high flexibility.

- Easy Gasket Replacement: Divided calibration/cleaning chamber allows for simple gasket changes.

- Extended Service Life: Enhanced seal longevity and reduced wear.

- ATEX Approved: Certification II 1GD c II for the complete fitting.

- Cost-Effective: Simplified installation, operation, and maintenance reduce overall costs.

- High Availability: Ensures the fitting is ready for use when needed.

- Seal Protection: Protective rinsing extends seal life.

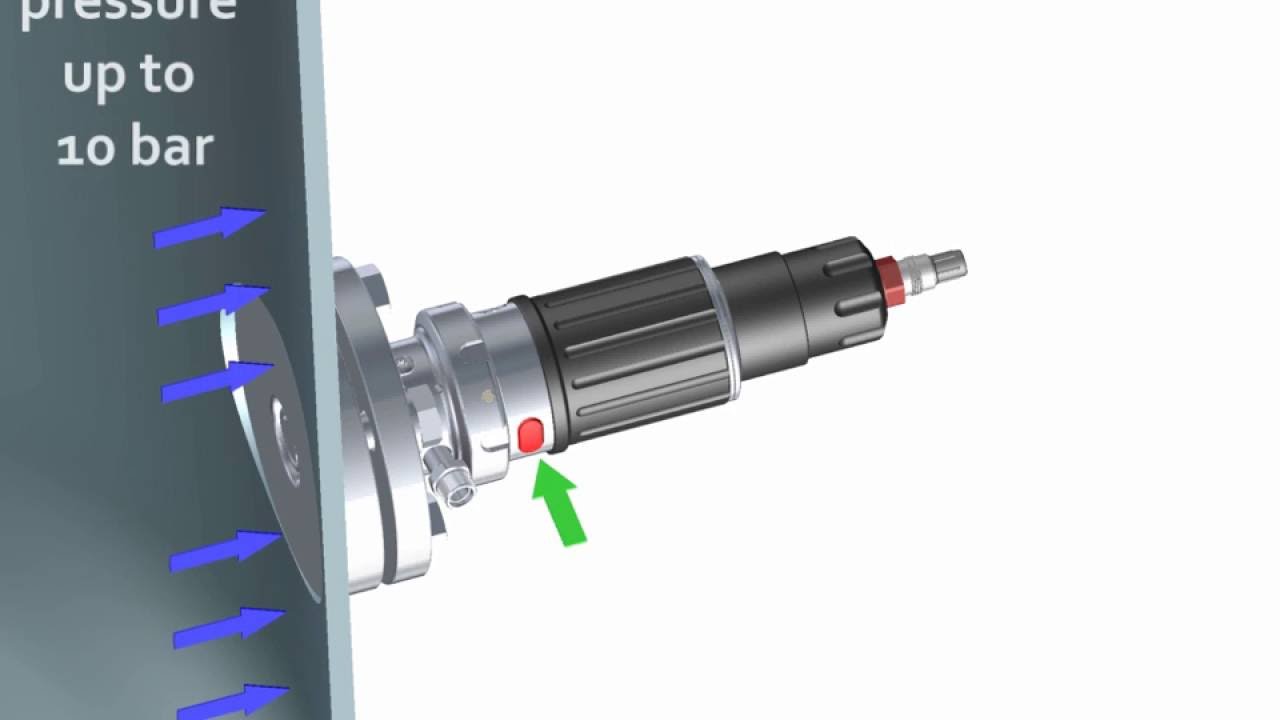

- SensoLock Safety: High operational safety with integrated check valves and limit switches.

- Quick and uncomplicated replacement of calibration chamber and immersion tube.

- On-Site Maintenance: All maintenance tasks can be performed on-site.

- Cyclone Rinsing: Provides optimal cleaning effect.

- Superior Sensor Immersion Depth: Standard sensor length (225 mm) even for large immersion depths.

- Multiple connection options available, including a flange version with a scraper ring.

- Modular design allows replacement of process-wetted materials such as PEEK, PVDF, PP, 1.4571, and Hastelloy.

- Carbon-fiber-reinforced plastics offer high pressure and temperature resistance.

- Special Sensor Version: Available for sensors with pressurizable liquid electrolyte.

- Easy Installation: Clear hose connections and central multiplug for all media and control air.

Download PDF: Knick SensoGate WA 130 Datasheet

WA 130 H - SensoGate Retractable Fitting

The SensoGate WA 130 H is a hygienic, pneumatically operated retractable fitting designed for use with fully automatic Unical controllers. Its modular design ensures minimal maintenance, maximum flexibility, and ease of use. This genuine Plug & Play solution features a central multiplug that connects all rinsing, cleaning, and calibration media, along with control air and limit position mechanisms. With complete interior media routing, the SensoGate WA 130 H offers a safe and convenient setup, minimizing media entrainment and reliably protecting the limit-position mechanism.

Facts and Features

Steam-Sterilizability: Validated for all process-wetted parts including the rinsing/calibration chamber.

Steam-Sterilizability: Validated for all process-wetted parts including the rinsing/calibration chamber.- Dirt-resistant with interior media routing and an integrated limit-position mechanism.

- Directed Flow Rinsing: Rinses the process seal from both the process side and inside the fitting.

- Cyclone Rinsing: Provides optimal sensor cleaning effect.

- Safe Separation: Prevents re-contamination during probe movement.

- Double Gaskets with Leakage Bores: Prevents microbial contamination of the drive.

- Broad Applications: Suitable for hygienic conditions.

- Simplified installation, operation, and maintenance reduce overall costs.

- High Availability: Ensures the fitting is ready for use when needed.

- Seal Protection: Protective rinsing extends seal life.

- SensoLock Safety: High operational safety with integrated check valves and limit switches.

- Quick and uncomplicated replacement of calibration chamber and immersion tube.

- On-Site Maintenance: All maintenance tasks can be performed on-site.

- Superior Immersion Depth: Standard sensor length (225 mm) even for large immersion depths.

- Multiple connection options available.

- High-Quality Materials: Process-wetted parts made of electropolished stainless steel 1.4404.

- Modular Design: Allows specific replacement of components.

- Available for sensors with pressurizable liquid electrolyte.

- SIP and CIP Capable: Suitable for sterilization and cleaning in place in the process and calibration chamber.

- Easy Installation: Clear hose connections and central multiplug for all media and control air.

Download PDF: Knick SensoGate WA 130 H Datasheet

WA 131 - SensoGate Retractable Fitting

The SensoGate WA 131 is a universal, pneumatically operated retractable fitting designed with a modular structure, ideal for simple controllers. Based on the proven SensoGate modular design principle, the WA 131 is perfect for applications that do not require fully automated control but still benefit from superior SensoGate technology. It is suitable for automatic or semi-automatic connections to commercially available or custom-developed control units.

Key Features:

Compact and Smooth Design: Dirt-resistant with a sleek appearance.

Compact and Smooth Design: Dirt-resistant with a sleek appearance.- Modular Design: Ensures minimal maintenance costs and maximum flexibility.

- Easy Gasket Replacement: Divided calibration/cleaning chamber allows for simple gasket changes.

- Extended Service Life: Enhanced seal longevity and reduced wear.

- ATEX Approved: Certification II 1GD c II for the complete fitting.

- Cost-Effective: Simplified installation, operation, and maintenance reduce overall costs.

- High Availability: Ensures the fitting is ready for use when needed.

- Seal Protection: Protective rinsing extends seal life.

- SensoLock Safety: High operational safety with integrated check valves and limit switches.

- Quick and uncomplicated replacement of calibration chamber and immersion tube.

- On-Site Maintenance: All maintenance tasks can be performed on-site.

- Cyclone Rinsing: Provides optimal cleaning effect.

- Superior Sensor Immersion Depth: Standard sensor length (225 mm) even for large immersion depths.

- Versatile Process Connections: Multiple connection options available, including a flange version with a scraper ring.

- Modular design allows replacement of process-wetted materials such as PEEK, PVDF, PP, 1.4571, and Hastelloy.

- High-Performance Plastics: Carbon-fibre-reinforced plastics offer high pressure and temperature resistance.

- Special Sensor Version: Available for sensors with pressurizable liquid electrolyte.

- Variable and Affordable: Suitable for various applications with reasonable pricing.

Download PDF: Knick WA 131 SensoGate Datasheet

WA 131 H - SensoGate Retractable Fitting

The SensoGate WA 131 H is a pneumatically operated retractable fitting designed for simple, commercially available controllers in hygiene applications. Based on the proven SensoGate modular design principle, the WA 131 H is perfect for hygienic applications with automatic or semi-automatic connections to simple commercially available or custom-developed control units.

Key Features:

Steam-Sterilizability: Validated for all process-wetted parts including the rinsing/calibration chamber.

Steam-Sterilizability: Validated for all process-wetted parts including the rinsing/calibration chamber.- Directed Flow Rinsing: Rinses the process seal from both the process side and inside the fitting.

- Cyclone Rinsing: Provides optimal sensor cleaning effect.

- Safe Separation: Prevents re-contamination during probe movement.

- Double Gaskets with Leakage Bores: Prevents microbial contamination of the drive.

- Broad Applications: Suitable for hygienic conditions.

- Cost-Effective: Simplified installation, operation, and maintenance reduce overall costs.

- High Availability: Ensures the fitting is ready for use when needed.

- Seal Protection: Protective rinsing extends seal life.

- SensoLock Safety: High operational safety with integrated check valves and limit switches.

- Easy Component Replacement: Quick and uncomplicated replacement of calibration chamber and immersion tube.

- On-Site Maintenance: All maintenance tasks can be performed on-site.

- Superior Sensor Immersion Depth: Standard sensor length (225 mm) even for large immersion depths.

- Versatile Process Connections: Multiple connection options available.

- High-Quality Materials: Process-wetted parts made of electropolished stainless steel 1.4404.

- Modular Design: Allows specific replacement of components.

- Special Sensor Version: Available for sensors with pressurizable liquid electrolyte.

- SIP and CIP Capable: Suitable for sterilization and cleaning in place in the process and calibration chamber.

- Variable and Affordable: Suitable for various applications with reasonable pricing.

Download PDF: Knick SensoGate WA 131 H Datasheet

WA 131 M - SensoGate Retractable Fitting

The SensoGate WA 131 M is an innovative manual retractable fitting equipped with a safe-to-operate rotary drive. Ideal for applications where pneumatic fittings are not essential, the WA 131 M offers the same compatibility and high performance as its pneumatically controlled counterparts. It shares common rinsing chambers, process connections, and materials, ensuring seamless integration into existing systems.

Key Features:

Compact and Smooth Design: Dirt-resistant with a sleek appearance.

Compact and Smooth Design: Dirt-resistant with a sleek appearance.- Modular Design: Ensures minimal maintenance costs and maximum flexibility.

- Easy Seal Replacement: Divided calibration/cleaning chamber allows for simple seal changes.

- Extended Service Life: Enhanced seal longevity and reduced wear.

- ATEX Approved: Certification II 1GD c II for the complete fitting.

- Cost-Effective: Simplified installation, operation, and maintenance reduce overall costs.

- High Availability: Ensures the fitting is ready for use when needed.

- Seal Protection: Protective rinsing extends seal life.

- SensoLock Safety: High operational safety with integrated limit switches.

- Easy Component Replacement: Quick and uncomplicated replacement of calibration chamber and immersion tube.

- On-Site Maintenance: All maintenance tasks can be performed on-site.

- Cyclone Rinsing: Provides optimal cleaning effect.

- Superior Sensor Immersion Depth: Standard sensor length (225 mm) even for large immersion depths.

- Versatile Process Connections: Multiple connection options available, including a flange version with a scraper ring.

- Material Specific Replacement: Modular design allows replacement of process-wetted materials such as PEEK, PVDF, PP, 1.4571, and Hastelloy.

- High-Performance Plastics: Carbon-fiber-reinforced plastics offer high pressure and temperature resistance.

- Special Sensor Version: Available for sensors with pressurizable liquid electrolyte.

Download PDF: Knick SensoGate WA 131 M Datasheet

WA 131 MH - SensoGate Retractable Fitting

The SensoGate WA 131 MH is an innovative manual retractable fitting with an easy-to-operate rotary drive, designed for hygienic applications. It is fully compatible with Knick's automatic fittings, sharing common rinsing chambers, process connections, and materials, ensuring seamless integration into existing systems where pneumatic fittings are not essential.

Key Features:

Steam-Sterilizability: Validated for all process-wetted parts including the rinsing/calibration chamber.

Steam-Sterilizability: Validated for all process-wetted parts including the rinsing/calibration chamber.- Directed Flow Rinsing: Rinses the process seal from both the process side and inside the fitting.

- Cyclone Rinsing: Provides optimal sensor cleaning effect.

- Safe Separation: Prevents re-contamination during probe movement.

- Double Gaskets with Leakage Bores: Prevent microbial contamination of the drive.

- Broad Applications: Suitable for hygienic conditions.

- Cost-Effective: Simplified installation, operation, and maintenance reduce overall costs.

- High Availability: Ensures the fitting is ready for use when needed.

- Seal Protection: Protective rinsing extends seal life.

- SensoLock Safety: High operational safety with integrated limit switches.

- Quick and uncomplicated replacement of calibration chamber and immersion tube.

- On-Site Maintenance: All maintenance tasks can be performed on-site.

- Superior Sensor Immersion Depth: Standard sensor length (225 mm) even for large immersion depths.

- Versatile Process Connections: Multiple connection options available.

- High-Quality Materials: Process-wetted parts made of electropolished stainless steel 1.4404.

- Modular Design: Allows specific replacement of components.

- Special Sensor Version: Available for sensors with pressurizable liquid electrolyte.

- SIP and CIP Capable: Suitable for sterilization and cleaning in place in the process and calibration chamber.

- Variable and Affordable: Suitable for various applications with reasonable pricing

Download PDF: Knick SensoGate WA 131 MH Datasheet

WA 132/133 (M) - SensoGate Retractable Fitting

The SensoGate WA 132 and WA 133 (M) are ultra-resistant retractable fittings designed for chemically demanding environments. Featuring a fully modular design, these fittings ensure high chemical resistance with all process-wetted parts made of PTFE. They support both pneumatic and manual operation, and are compatible with PG 13.5 sensors (225 mm length) and liquid-filled sensors (250 mm length). The modular design allows for quick replacement of the PTFE immersion tube and easy maintenance of the split calibration chamber, ensuring long-term reliability and ease of use.

Key Features:

High Chemical Resistance: All process-wetted parts are made of PTFE, providing anti-adhesive properties and good resistance to hot water, and are FDA compliant.

High Chemical Resistance: All process-wetted parts are made of PTFE, providing anti-adhesive properties and good resistance to hot water, and are FDA compliant.- Modular Design: Fully modular concept allows for easy replacement of immersion tube and calibration chamber.

- Durable Construction: PTFE calibration chamber is encased in a stainless steel frame, preventing cold flow and wear.

- Effective Cleaning: Cyclone rinsing ensures thorough sensor cleaning.

- Sensor Compatibility: Operates with PG 13.5 sensors or liquid-filled sensors.

- System Integration: Compatible with Unical 9000/Uniclean 900 systems.

- Operational Flexibility: Available in both pneumatic and manual versions.

- Optimal Performance: Designed for use with lined fittings for enhanced durability.

Available Versions:

- Pneumatic Versions: Compatible with fully automatic Unical 9000 system or controllers from other manufacturers.

- Manual Version: Offered for applications requiring manual operation.

- Immersion Depth Options: Two different immersion depths allow for universal use.

- Customizable Process Adaptations: Includes versions suitable for PFA-lined sight glass fittings.

Download PDF: Knick SensoGate WA 132 Datasheet

Download PDF: Knick SensoGate WA 133 M Datasheet

Download PDF: Knick SensoGate WA 133 Datasheet

Supplied by DP-Flow

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222